Products

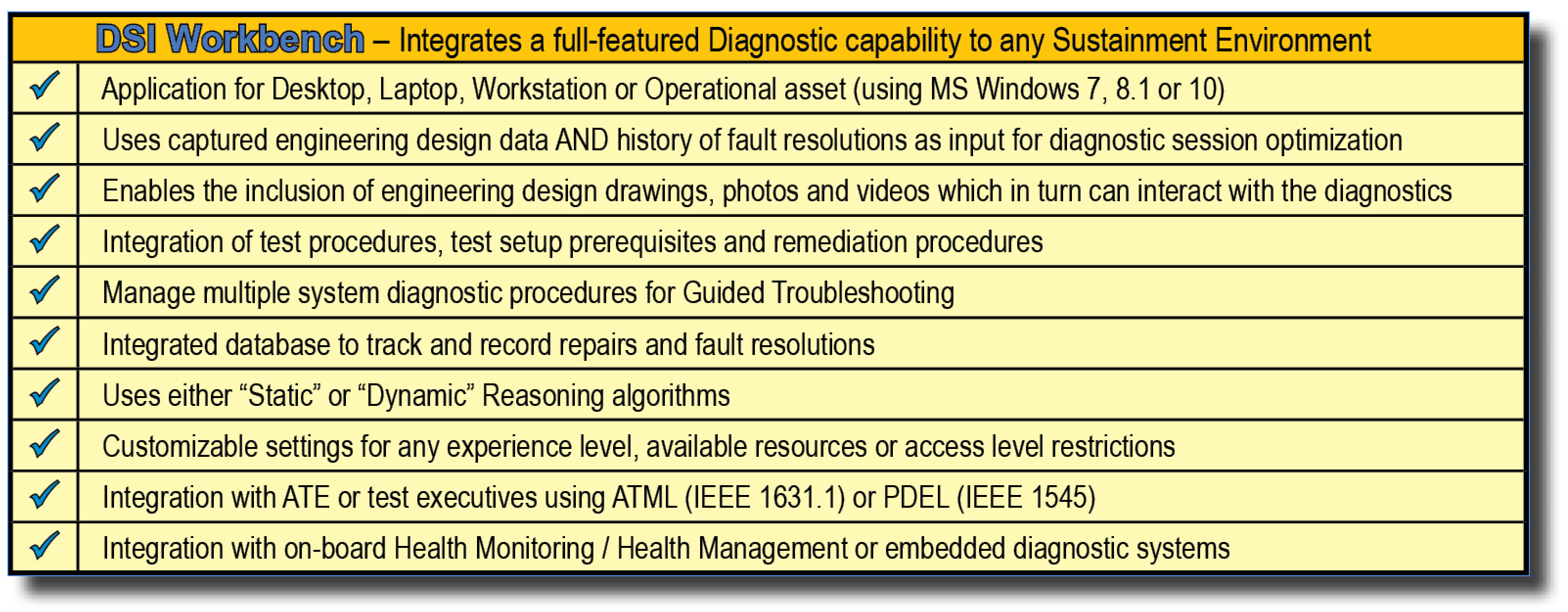

DSI Workbench

Guided Troubleshooting and Embedded Diagnostics for the Technician

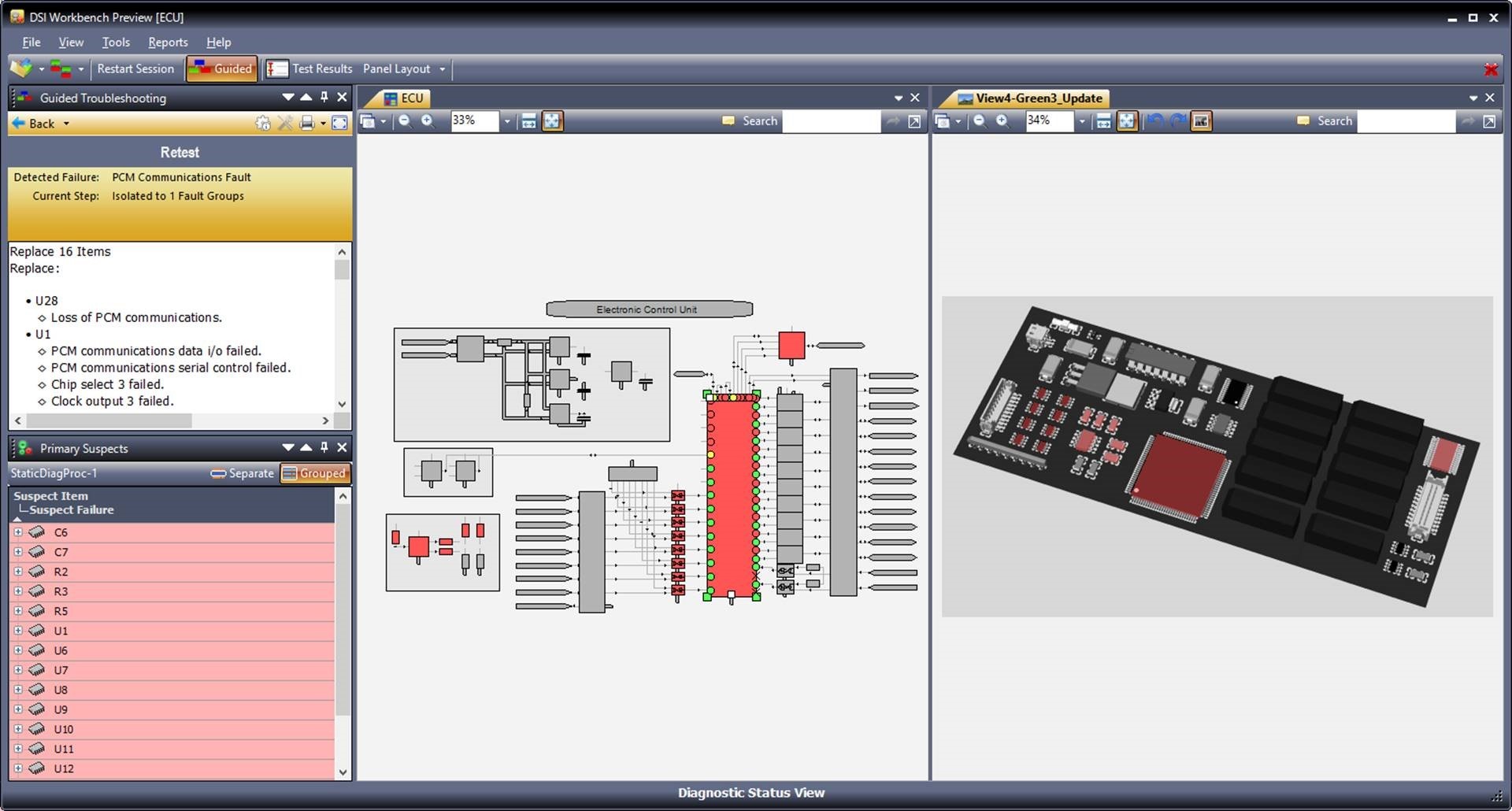

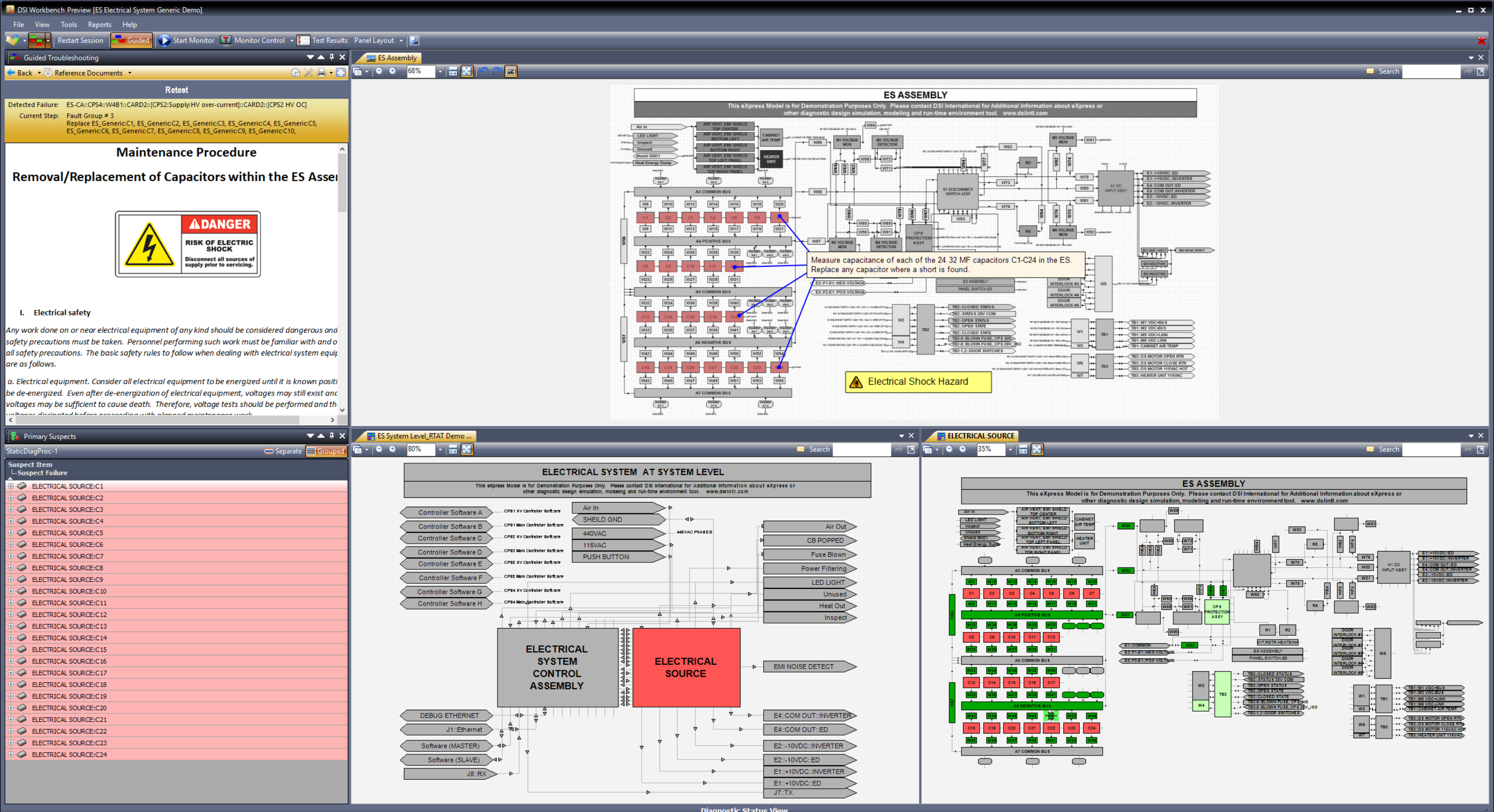

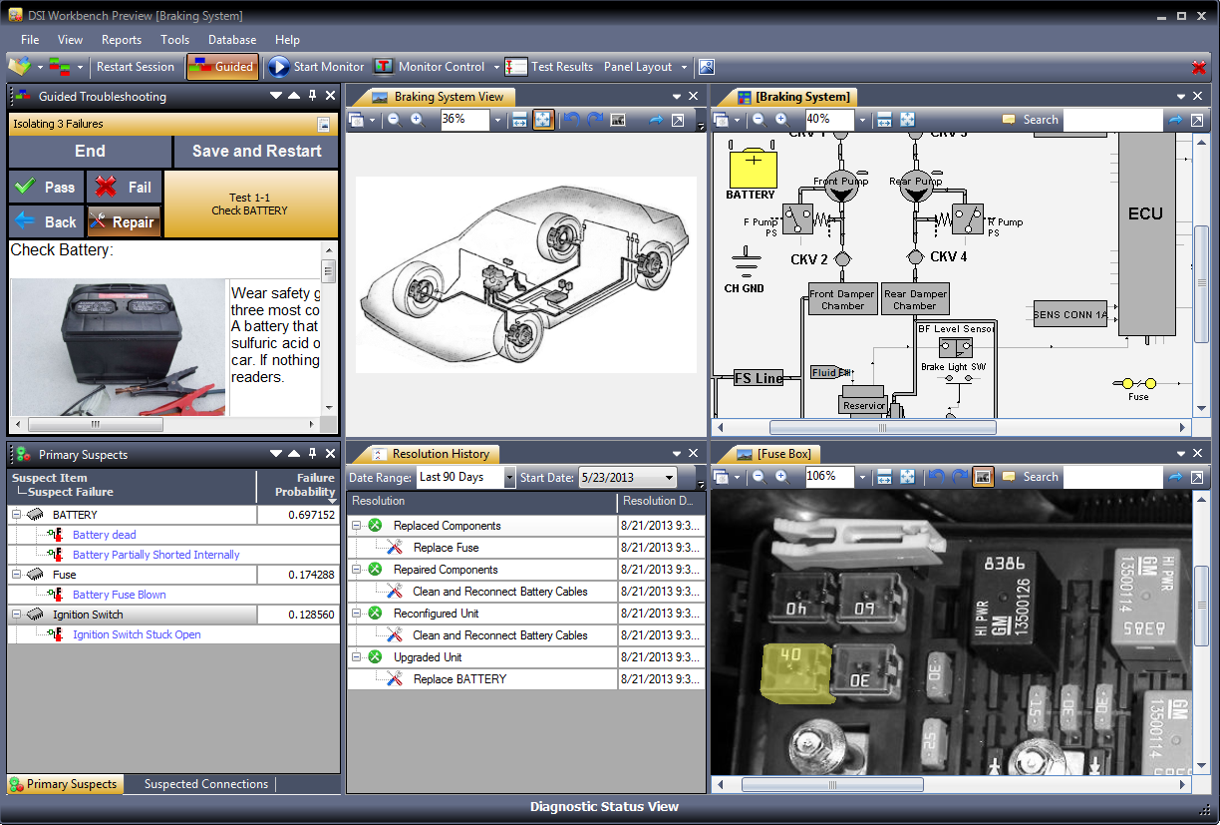

DSI Workbench allows for deployment of eXpress or user supplied diagnostics within production and maintenance troubleshooting environments. DSI Workbench facilitates the integration of diagnostic design views, engineering views, photos and videos within an integrated environment.

Full Product Lifecycle Application

DSI Workbench can bring the designer’s and maintainer’s captured knowledge into the hands of technicians and maintainers regardless if they’re servicing more commonplace commercial systems or very large and complex defense and space systems.

The DSI Workbench application contains an integrated Diagnostic Reasoning, enabling it to be deployed in a wide variety of high-end applications or environments:

Utility in the Design Development Lifecycle

• Desktop or Laptop for Design Reviews and Maintenance Demonstrations;

• Production or Laboratory Workstation to Guide or Train Technicians

Utility in the Sustainment Lifecycle

• Production or Laboratory Workstation to Guide Technicians to enrich and optimize Fault Isolation activities;

• Production or Depot to perform “Diagnostic Reasoning” to guide the ATE, or “Automatic Test Solution” (ATS);

• Using the DSI Workbench API;

• Embedded with the on-board test executive to perform as the “Diagnostic Executive” and “Diagnostic Reasoner”.

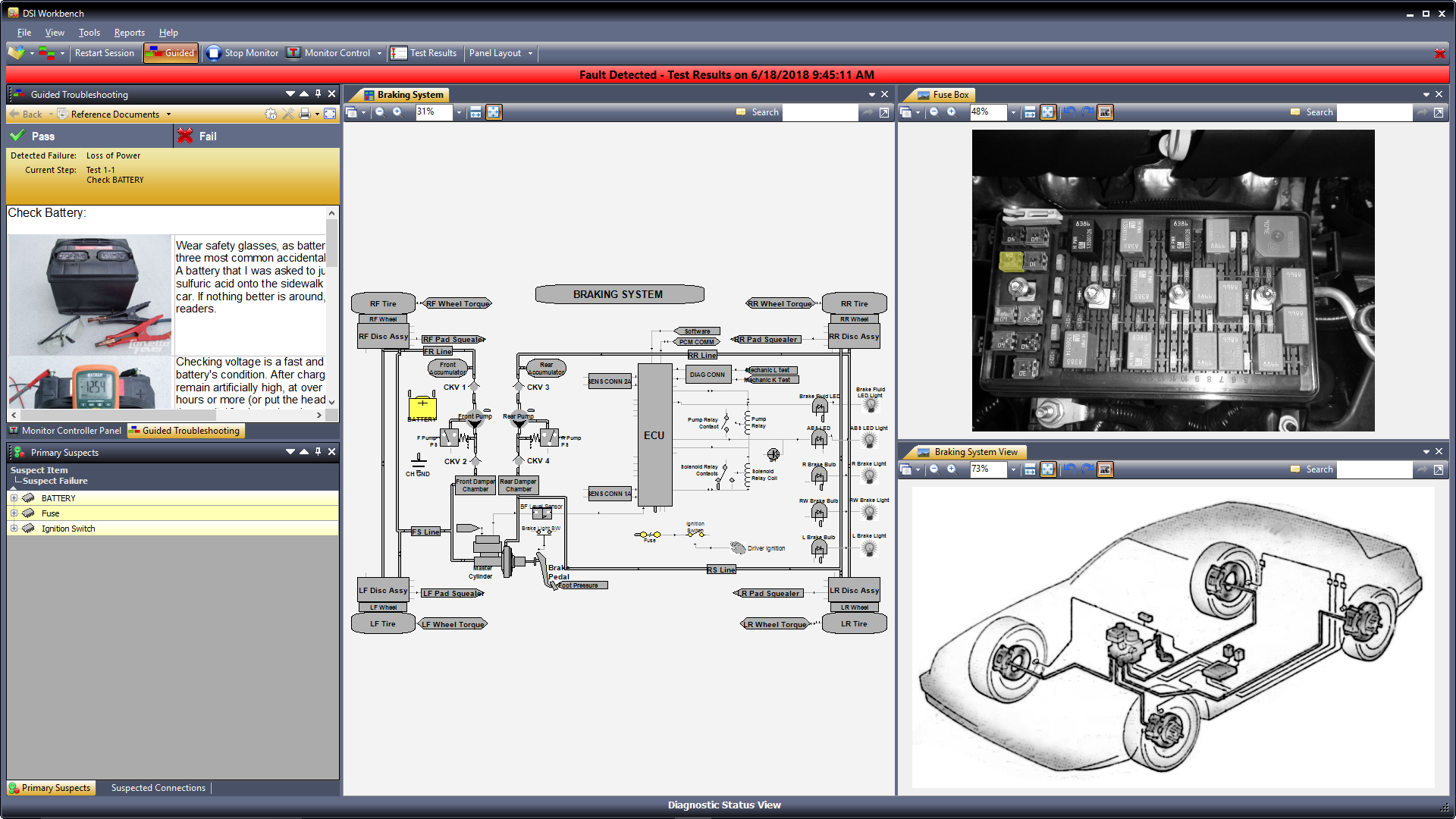

Utility in Health Monitoring Mode

DSI Workbench can be set to “Monitor Mode” to function with the “pass/fail” Test Results from a Automatic Test Equipment (ATE). When any test fails, it is immediately signified by the red horizontal bar extending across the top of the display. From this point, the technician can continue with any additional testing as needed to isolate to smaller fault groups or to a single component.

Utility in Guided Troubleshooting Mode

DSI Workbench can be set to “Guided Mode” to function as Portable Electronic Maintenance Aide (PEMA) or Interactive Electronic Technical Manual (IETM) to bring the knowledge of the design to the Technician in a “Guided Troubleshooting” application.

Static or Dynamic Reasoning Options

DSI Workbench comes standard with a “static” (predetermined test sequencing) diagnostic reasoning capability. During the Development Lifecycle, engineering analyses and Test development is initially calculated from the perspective of the performing of static testing capabilities. This is required by most military applications as static reasoning offers a mechanism to fully expose and document the test sequencing of predetermined test and maintenance procedures for fault isolation or troubleshooting activities.

A “Dynamic Reasoning” option is available for DSI Workbench that enables more alternative testing and diagnoses to be based on more dynamic constraints. The sequencing of the testing will depend upon an infinite number of factors or criterion during that particular “Diagnostic Session”.

The two most fundamental requirements of a Dynamic Reasoning application would be to fully accommodate the free-form ability to “Skip”, or “Back-up” Test Scenarios. Examples of such scenarios where the technician is “Unable to Perform the Test” may be due to any reason, including the unavailability of on-demand Resources (i.e. Safety, Time, Labor, Test Equipment, Skill Level or Security Access Rights).

DSI’s Dynamic Reasoning is able to be verified during the Development Lifecycle by using the “Desktop Fault Isolation” feature in eXpress, and/or the advanced “TestDRIVE” utility supplied with the standalone DSI Dynamic Reasoner or the DSI Embedded Reasoner.

Embedded into the equipment to perform the “Diagnostic Reasoning” using the asset’s Health Monitoring system BIT and displaying the results on a native application to visualize Health Status and/or for continued interactive test sequencing;

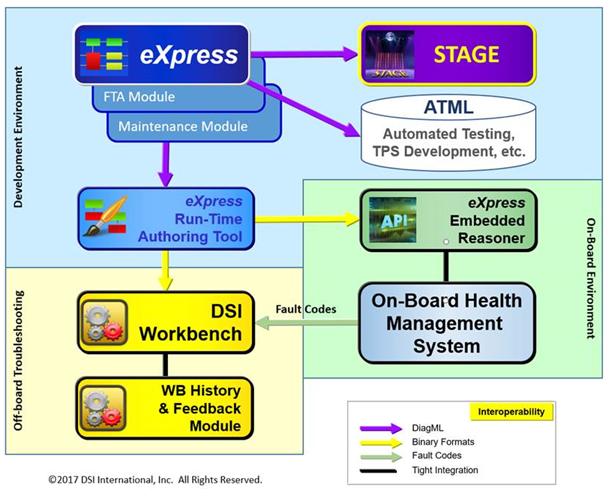

Advanced Applications – On-board Health Management

DSI Workbench can also be used in advanced Health Management applications where the hosting system has computing resources available. In this role, considerably more effective health assessment interactivity is gained from the use of the Diagnostic Reasoner and the Diagnostic Executive “packaged” within DSI Workbench, along with the host’s on-board Health Monitoring (or embedded BIT) and Test Executive capabilities.

When used in this high-end capability, DSI Workbench is able to offer a wide array of advanced and customizable options to any on-board Health Management system. Since this approach ensures direct traceability back to the digital design, it offers a holistic method that is able to be easily and immediately updated throughout the full Product Lifecycle.

Request an Evaluation Copy of DSI Workbench

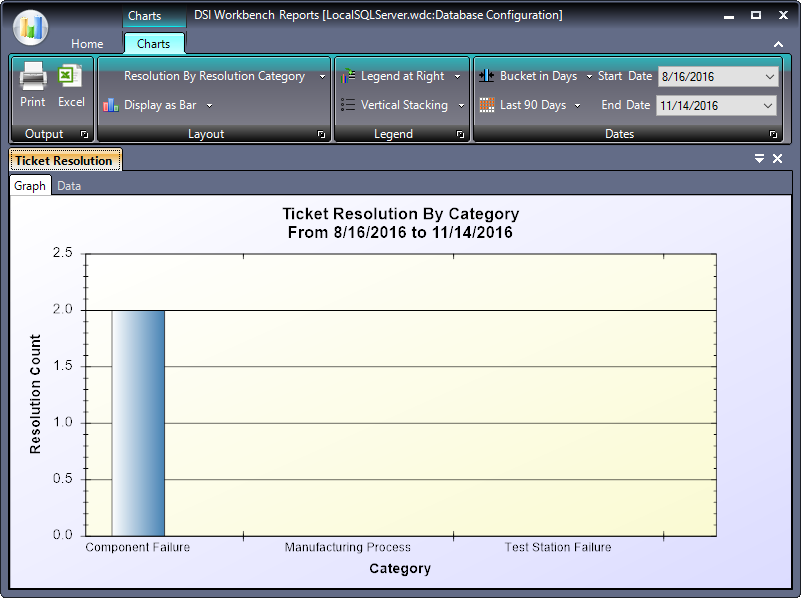

DSI Workbench History & Feedback Module

The DSI Workbench History & Feedback module tracks and records maintenance actions and fault resolutions in DSI Workbench. The Workbench Reports application provides reports on resolution history and maintenance performance.

- Setup and maintain troubleshooting tickets.

- Tracks fault repairs.

- Tracks and reports upon fault resolutions.

- Provides reporting for administrators to gage the performance of diagnostic and maintenance actions.

- Supports S1000D technical publication environments

DSI Workbench can bring the designer’s and maintainer’s captured knowledge into the hands of technicians and maintainers regardless if they’re servicing more commonplace commercial systems or in larger or more complex systems.

Notice the lower-middle window in the image below. This is an example of the historical data that can be used to inform the maintainer of the resolutions to similar failures that were most recently logged into the local or remotely accessed database.

DSI Workbench API

The DSI Workbench Application Programmable Interface is an optional module for DSI Workbench. It allows for embedding the DSI Workbench diagnostic reasoning, controls, reporting and data tracking capabilities into a custom user developed application. The API provides feedback from databases and user prompts into reporting of diagnostic actions taken.

- Allows for deployment of eXpress generated static diagnostics to work with user supplied tests executives and maintenance software.

- Automated reporting of diagnostic results based upon supplied test conditions.

- Allows customization and configuration of diagnostic reporting methods.

- Supports tree-based diagnostic, dynamic diagnostic sessions and fast fault signature lookup.

- ** For more information regarding DSI Workbench API, click here.

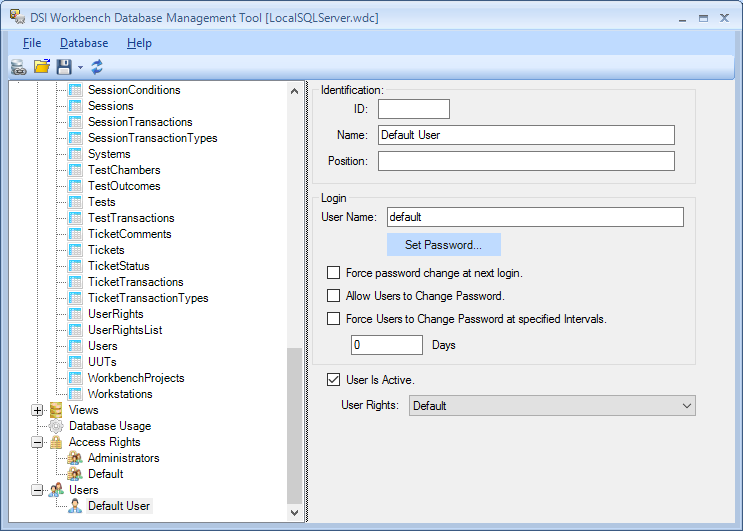

DSI Workbench Database Management Tool

The DSI Workbench Database Management Tool allows database administrators to create, setup and manage databases used for storing repair and fault resolution records from the DSI Workbench Database.

Using this tool, the administrator can create and setup a new database to a predefined database template. This includes setting test locations, operating conditions, resolution categories, resolution types, user rights and users (note: administrators may also directly add and administer users directly within DSI Workbench) all of which can be directly stored in the template and applied during the initial creation of the database.

DSI Workbench Report Viewer

The DSI Workbench Report Viewer automatically generates reports using the data stored in the DSI Workbench database. The tool allows project planners and administrators to run queries and checks to determine the effectiveness of currently deployed diagnostics and identify areas needing improvement or redesign. In addition, more specific inquires can be performed to examine the state or status of specific units under test and repair.